Working with 8 medical, business, law and engineering students, we created a low-cost, simple negative pressure wound therapy

Media Coverage

i. Research

Interviewing wound care specialists and discussing use with patients we uncovered a need for an affordable, simple negative pressure wound therapy for use on post-surgical incisions.

ii. Brainstorming

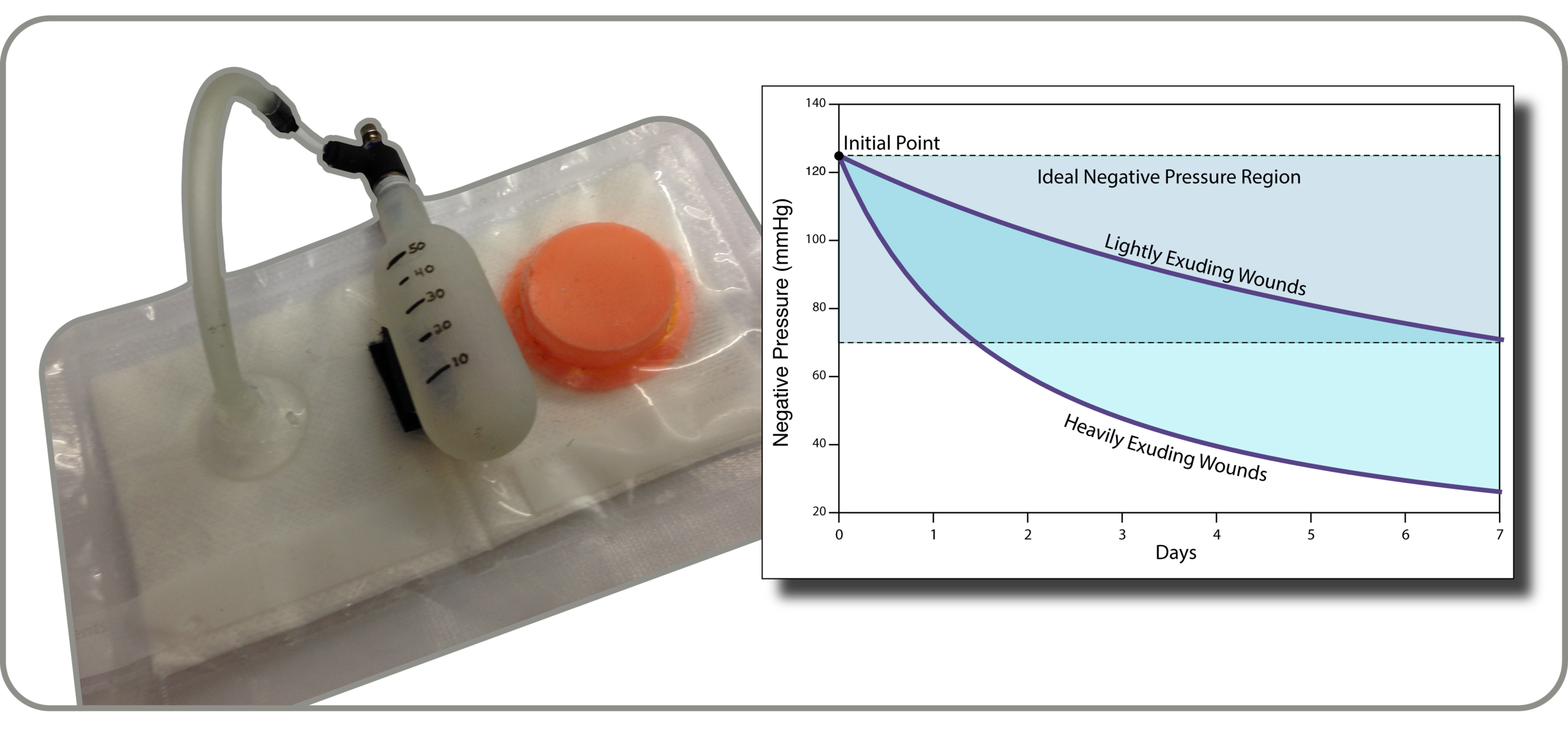

While competitors use pumps, we searched the literature for a way to make a silent, battery-free vacuum that wouldn't disturb the patient. We considered shape memory foams, sorption and chemical reactions. We finalized on a pre-evacuated canister which equalizes pressure overtime with the wound bed.

iii. Prototyping

The use of an evacuated canister is perfect for this system because it is capable of both creating a vacuum and collecting exudate that is removed from the wound bed. We are working towards a see through canister that will allow caregivers to read off exactly how much exudate has been collected.

iv. Testing and Modeling

We continue to develop this product. We are currently developing a nylon, all-in-one canister for easy connection to the bandage and simple reading of exudate levels.

To measure pressure levels, we designed a silicone "popper" which buckles under pressure but pops back up when pressure is lost, indicating it is time to cheaply replace the canister.

vi. User Feedback

Throughout the prototyping, we continued to elicit feedback from physicians and nurses to refine the concept and make it as easy to use as possible.

v. The Ask

Presenting to innovators, designers and business professors and medical device executives, we pitched our product and business plan. We gained tremendous feedback through this process and continue to refine the product and business plan.

vi. Patent Protection

To protect the core of our technology, the lawyers and engineers on our team have collaborated to draft claims for a filed provisional.